SPINDLES FOR DRILLING

205000.00 INR/Piece

Product Details:

- Features High durability, precision concentricity, interchangeable assemblies

- Operate Method Automatic / Manual / Semi-Automatic

- Cutting Speed Up to 4500 rpm (varies by spec)

- Cutting Force High

- Operation Type Drilling

- Material Alloy Steel / Hardened Steel

- Shape Cylindrical

- Click to View more

X

SPINDLES FOR DRILLING Price And Quantity

- 205000.00 INR/Piece

- 205000.00 - 560000.00 INR/Piece

- 1 Piece

- 0.005 mm

- Readily available

- Industrial drilling, tapping, and milling processes

- ISO / BT / HSK / Customized

- Dynamically balanced as per ISO standards

- Compatible with coolant supply

- Grease-packed or oil lubrication options

- Low-noise operation

SPINDLES FOR DRILLING Product Specifications

- High durability, precision concentricity, interchangeable assemblies

- 16 mm to 50 mm (custom on request)

- 0.01 mm

- Rotary Cutter

- Up to 4500 rpm (varies by spec)

- Spindle

- Automatic / Manual / Semi-Automatic

- Drilling Spindle

- Drilling

- 58-62 HRC

- Uncoated, can be customized

- 150 mm to 500 mm (varies as per model)

- Precision Drilling

- High

- Up to 50 mm diameter (varies by model)

- Drilling Machine, CNC, Special Purpose Machines

- None or Anti-rust

- Cylindrical

- Up to 10 Nm (varies by spindle model)

- Alloy Steel / Hardened Steel

- 0.005 mm

- Readily available

- Industrial drilling, tapping, and milling processes

- ISO / BT / HSK / Customized

- Dynamically balanced as per ISO standards

- Compatible with coolant supply

- Grease-packed or oil lubrication options

- Low-noise operation

SPINDLES FOR DRILLING Trade Information

- 10 Piece Per Day

- 1 Days

Product Description

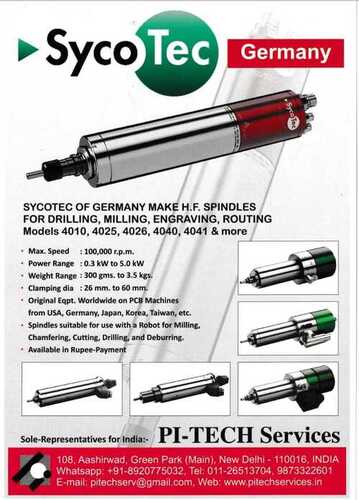

| Maximum Speed | 100,000 RPM |

| Power Range | 0.3 to 5.0 kW |

| Weight Range | 300 to 3.5 kg |

| Usage/Application | Drilling,Milling,Grinding,Engraving |

| Diameter | 26 to 60 mm (Clamping Diameter) |

| Brand | SycoTec |

Unmatched Precision and Reliability

Achieve outstanding drilling performance with spindles offering runout precision of 0.005 mm and dynamic balancing for steadfast reliability. Their robust construction using alloy or hardened steel guarantees superior concentricity, minimal vibration, and long-term durability. These spindles cater to high-precision industrial drilling, tapping, and milling applications, ensuring consistent quality even in demanding environments.

Versatile Mounting and Customization

Our spindles are compatible with multiple mounting interfaces, including ISO, BT, HSK, and tailored options upon request. Sizes range from 16 mm to 50 mm in diameter and lengths from 150 mm to 500 mm, fitting diverse application requirements. Custom coatings and dimensions are available to accommodate unique production needs and extend service life.

Enhanced Performance and Ease of Maintenance

Featuring easy lubrication options-grease or oil-along with efficient coolant compatibility, these spindles are engineered for smooth, continuous operation. Replacement parts are readily available to minimize downtime, and the spindles are suited to both automatic and manual operating methods, supporting flexible manufacturing workflows.

FAQ's of SPINDLES FOR DRILLING:

Q: How can these spindles improve precision in industrial drilling operations?

A: The spindles offer a runout precision of 0.005 mm and cutting accuracy of 0.01 mm, resulting in highly accurate holes with consistent diameter and finish. This level of precision reduces scrap and enhances the overall quality of drilled components.Q: What mounting interfaces are available for these drilling spindles?

A: They are compatible with ISO, BT, HSK, and custom mounting interfaces, ensuring integration with a wide range of drilling machines, CNCs, and special-purpose equipment.Q: Where can these spindles be used, and for what processes?

A: These spindles are suitable for use in diverse industrial settings, including CNC machining centers and drilling machines, for applications such as drilling, tapping, and milling processes.Q: What replacement and maintenance options are provided for these spindles?

A: Replacement parts are readily available through distributors, importers, and suppliers in India, ensuring minimal downtime. Lubrication options include both grease-packed and oil lubricated configurations.Q: When should one opt for customization of spindle size or coating?

A: Customization is recommended when specific machine requirements or challenging operating environments demand tailored dimensions or protective coatings. Custom options enhance compatibility and longevity in unique applications.Q: How does the spindle's cooling system contribute to performance and longevity?

A: The compatible coolant supply systems help regulate operating temperatures, reducing wear and tear, preventing overheating, and extending spindle service life, particularly during continuous or high-speed operations.Q: What are the benefits of the dynamically balanced construction?

A: Dynamic balancing as per ISO standards minimizes vibrations, ensures stable operation at high speeds up to 4500 rpm, and contributes to the spindle's low noise and high-precision performance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in ' SYCO TEC SPINDLES' category

|

PI-TECH SERVICES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |